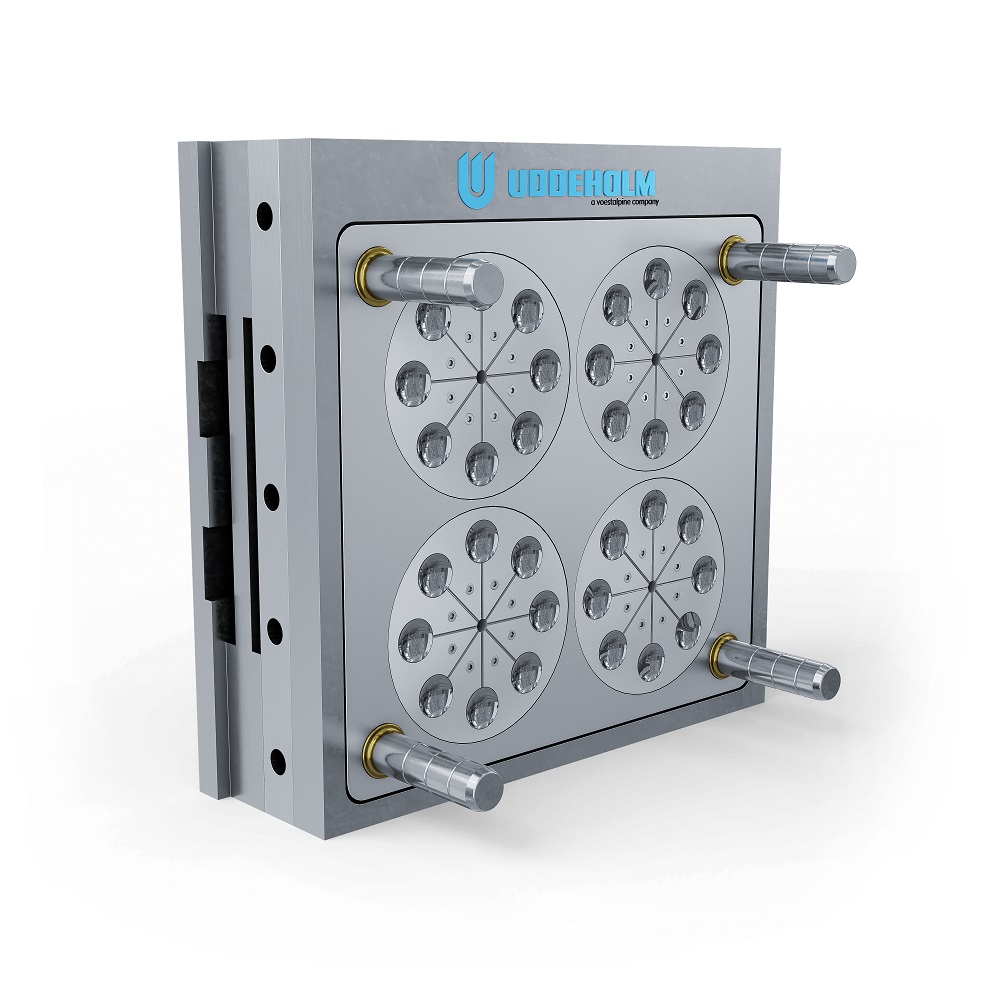

Uddeholm in Hagfors, Sweden, launches a new steel in the Tyrax family – a powder steel for additive manufacturing. Uddeholm Tyrax for AM is the answer to customer needs for increased tool performance in every detail.

AM steel offers superior toughness, polishability, excellent 3D printing properties and is also fossil free (scope 1 & 2).

“This is a brand new product – there is nothing like it on the market. With the powder, we take the good properties of Uddeholm Tyrax and add the widely recognized benefits of AM (additive manufacturing), such as better precision, significantly improved cycle times, and the best opportunity to create hybrid tools.” – Camilla Finnkvist, Uddeholm Plastic Manager

Uddeholm Tyrax for AM is the optimal choice for plastic applications that require a combination of corrosion, crack and abrasion resistance. Tyrax for AM is particularly suitable for the manufacture of highly demanding medical devices such as inhalers, insulin syringes and test tubes: products where every detail counts.

“With Uddeholm Tyrax for AM we can offer a unique product. Our tests show very impressive results, so we have an incredibly good product to offer the plastics market, which seems to have the potential to be used in other application areas in the future.” – Camilla Finnkvist, Uddeholm Plastic Manager

There are sustainability benefits through minimal material consumption when using AM powder, making additive manufacturing a greener option compared to traditional manufacturing. Uddeholm is also proud to present the world’s first Net Zero tool, made from Uddeholm Tyrax for AM, as part of the company’s green initiative.