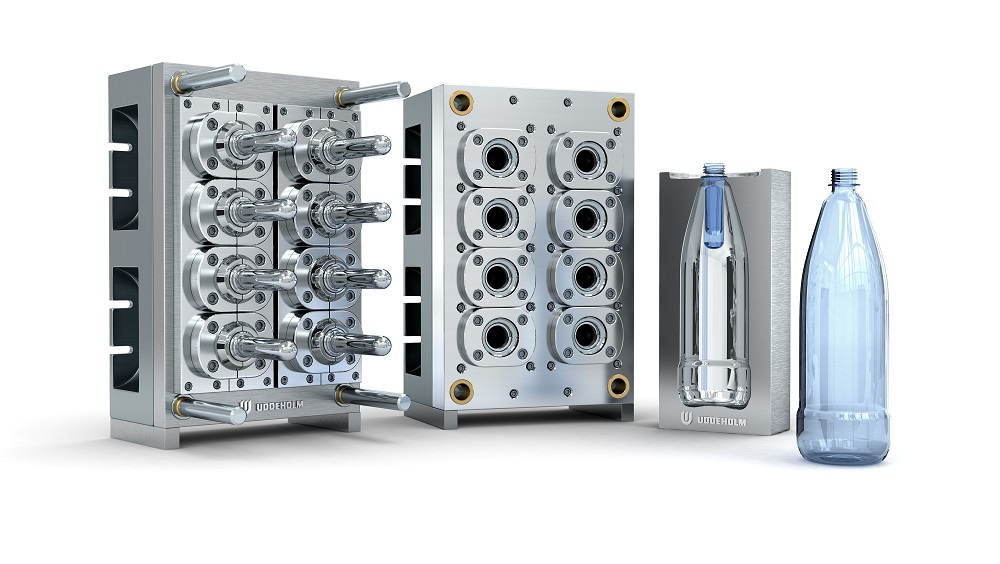

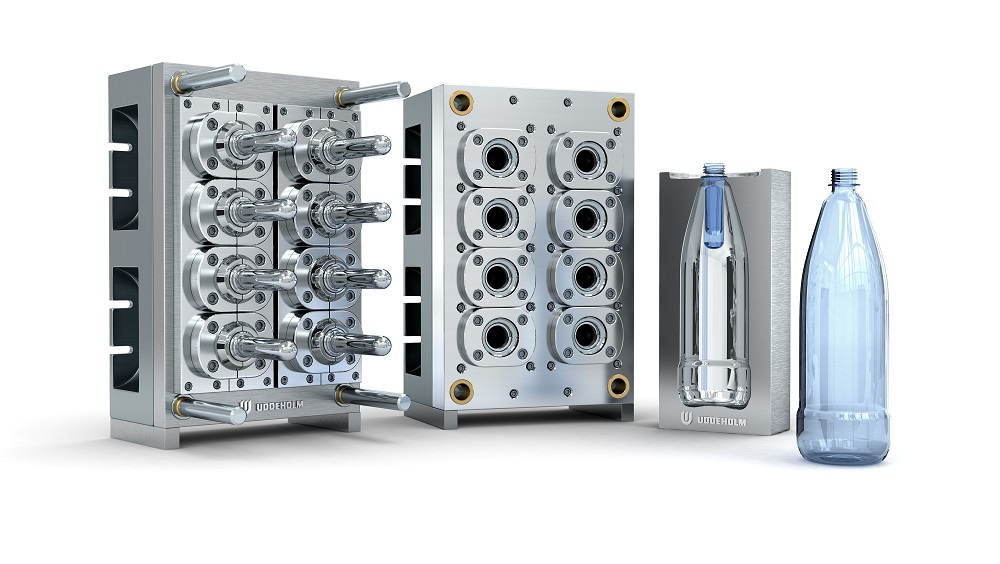

Alumec 89 is a high strength aluminium alloy recommended for blow moulds, prototype moulds and short run moulds with low demands on strength and wear resistance. The grade is also suitable for many types of engineering applications.

- Higher cutting speed means reduced machining time

- Light and easy to handle

- Reduced cycle times and less complicated cooling systems may be used

- Good corrosion resistance

- Can be surface treated

Benefits

- Excellent machinability: High cutting speeds, reduced machining time, lower tooling costs, quicker deliveries.

- Low weight: The low weight, which is approximately 1/3 of the weight of steel, allows easier and more convenient tool handling. Low inertia makes it possible to speed up closing and opening of moulds.

- High thermal conductivity: Cycle times are reduced and less complicated cooling systems may be used.

- Good stability: A special stress relieving operation guarantees minimal deformation during and after machining.

- Good resistance against all commonly used plastics materials.

- Suitable for surface treatments: Alumec 89 can be hard anodized, hard chromium or nickel plated for increased hardness, wear resistance and corrosion resistance.